Medical breathing air dryer medical compressed air systems boge plus means efficiency tools that make all the difference.

Medical air compressor system components shall be provided for which of these elements.

A filter should undergo a full inspection at least every four months.

As in any compressor system moisture is the enemy but in a hospital it s.

To better understand the medical air system we will follow the path of the air as it flows through the key components from the source to the patient.

The badge shall give the employee s name address of the medical lock the telephone number of the licensed physician for the compressed air project and contain instructions that in case of emergency of unknown or doubtful cause or illness the wearer shall be rushed to the medical lock.

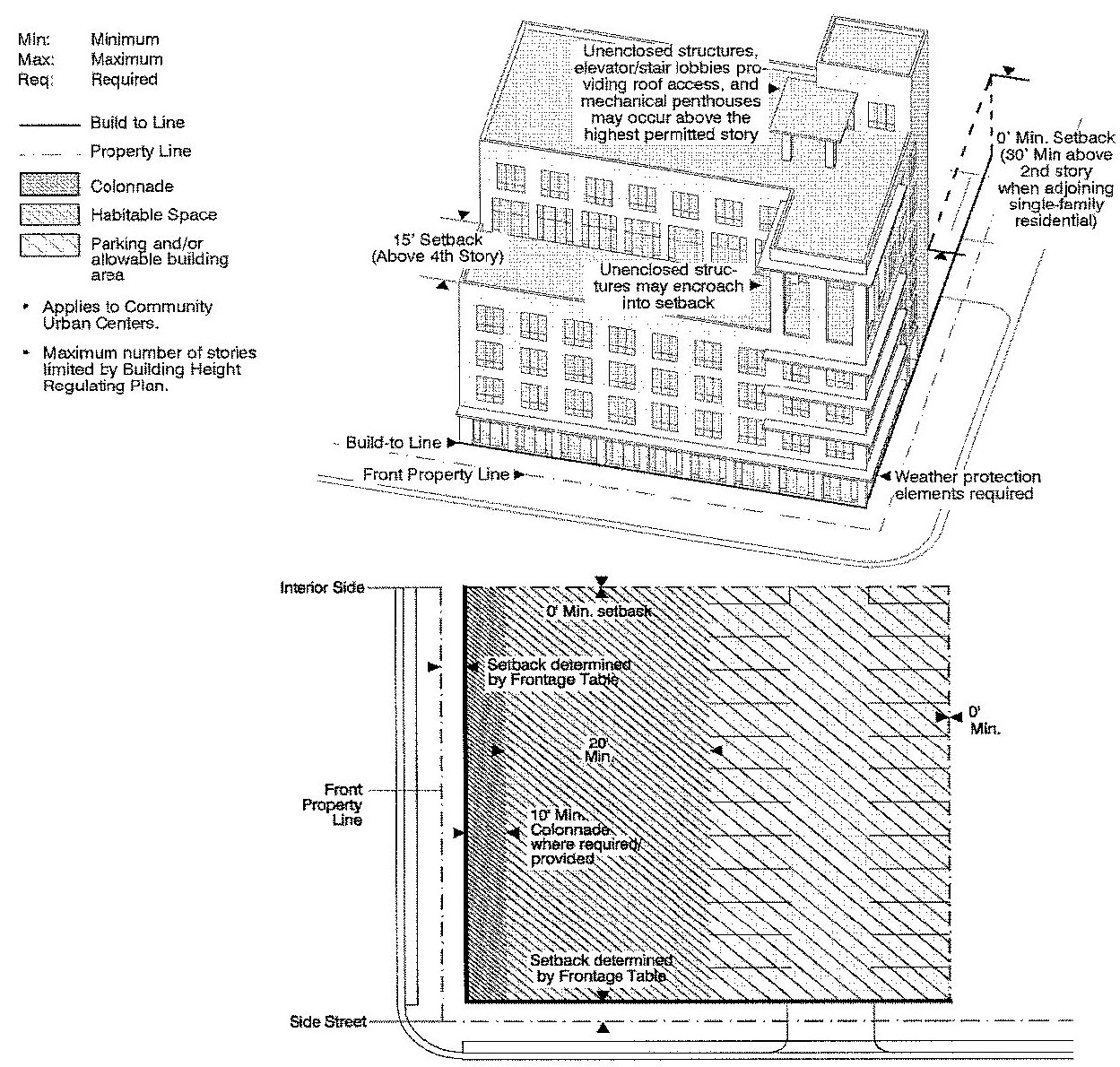

Due to the threat of moisture and other elements the piping contained throughout a medical air system must be non corrosive.

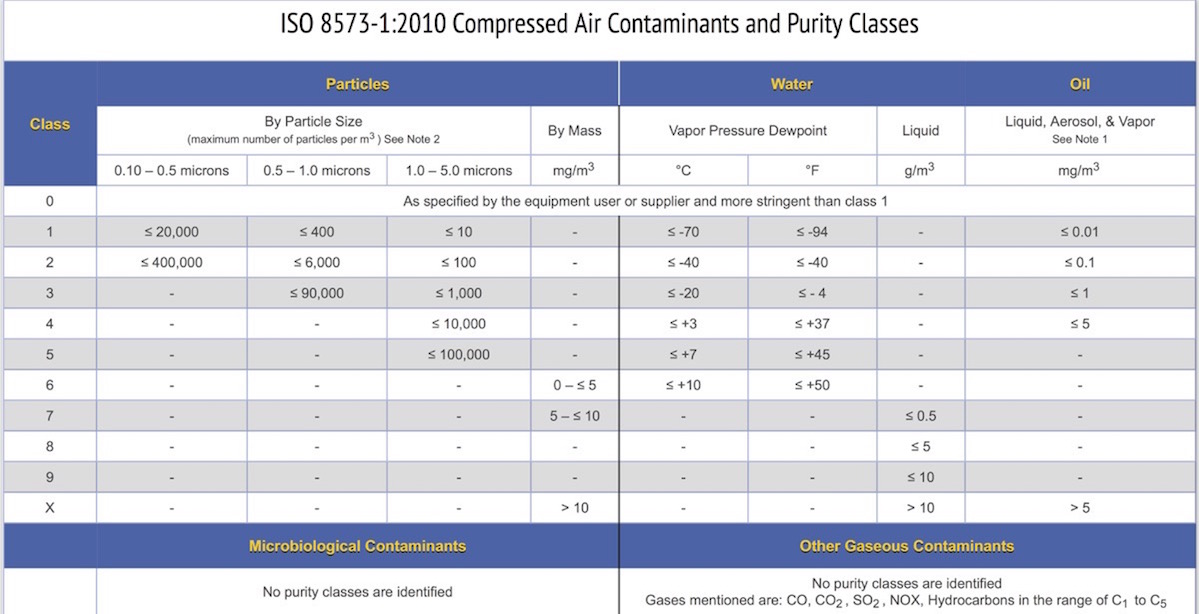

The most common contaminants are co2 dust oil and water vapor microorganisms aerosols rust.

Medical air compressor systems.

This way operators can determine the level of contaminants that try to enter the medical air during any given period.

Filtration is a necessity of course and hospital and medical compressor require particle free air.

Astroai digital tire inflator with pressure gauge 250 psi air chuck and compressor accessories heavy duty with rubber hose and quick connect coupler for 0 1 display resolution.

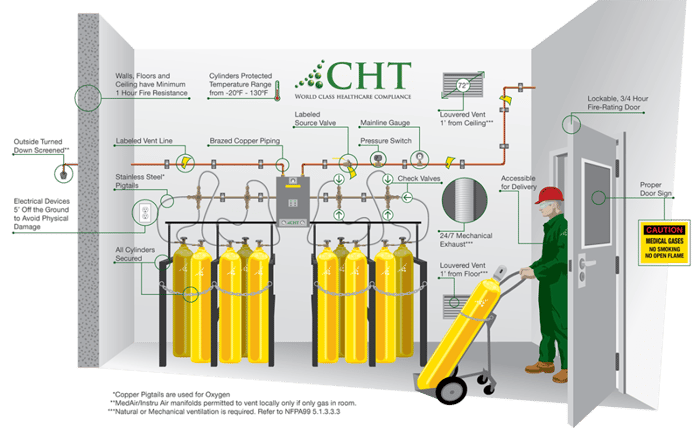

Medical air source requirements.

In all compressed air systems ambient air is drawn into the compressor and any contaminants present in the ambient air plus those introduced by the compressor itself will be present in the compressed outflow unless removed by a purification system.

All piping downstream of the compressors must be cleaned and specially rated for medical oxygen service.

Nfpa demands that two or more compressors be used for every medical air system.

In the event that any of the compressors in service fails the remaining unit s shall be able to maintain required compressed air at 100 percent of total system demand.

We show you right at the outset what your system could look like and certainly ensure that all system components work together in the best possible way.

22 79 1 used offer free shipping on eligible orders.

The multiplexing provided by alternating units also extends the life of the units and increases the system s.

The intake is usually located on the facility s roof.

Most compressors in these environments use multiple filters.

The logical place to start learning about the medical air system is the intake pipe of the compressor.

The benefits range from the planning stage to a safeguarded supply.

According to the most recent update of the nfpa 99 regulations the intake of the compressed air system is required to be at least 25 feet from any exhaust or vent 25 feet from the any source or collection of noxious fumes and 10 feet from a window.